Industrial manufacturing

Industrial manufacturing-small batch production

3D printing is the unique choice for small-batch, complex-structured and big-sized models, as the development of compatible materials, 3D printing is gradually used in the direct manufacturing, such as robotics, aerospace, jigs & fixtures, racing cars and car weightlights etc.

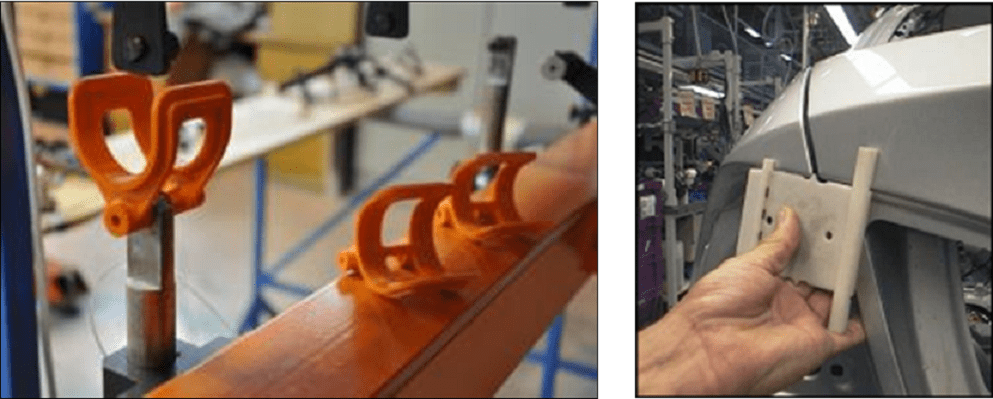

Industrial Manufacturing-3D printing jigs and textures

Tools are always required during the manufacturing process, and certain products and various fixtures, splints and gages can significantly improve the process while reducing production time and labor costs. But before 3D printing became more common, many companies couldn’t afford to customize their tools. When all kinds of affordable industrial and desktop 3D printers are popular, the situation will surely be different.

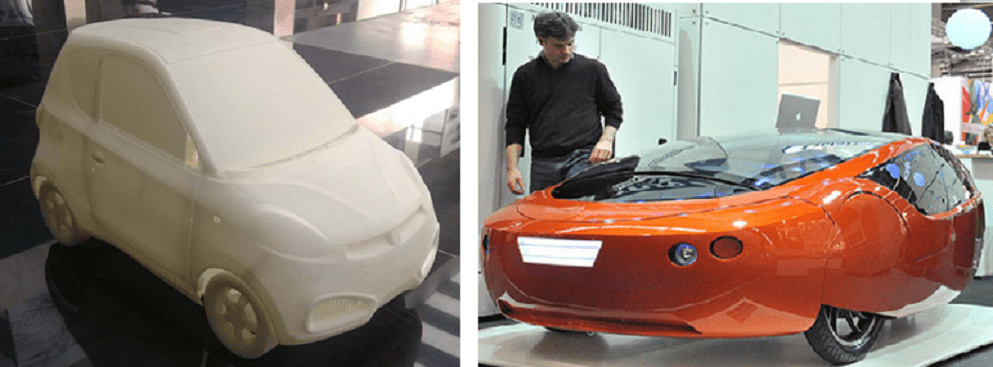

Industrial Manufacturing-3D printing in Automobile

First, 3D printing has faster speeds, lower component costs, and higher confidentiality. With 3D printing technology, conceptual models can be created in hours or days to help OEMs and component manufacturers optimize designs and accelerate product proof-of-concept processes.

Secondly, diverse material selection, different mechanical properties and precise functional prototyping allow manufacturers to correct errors and improve designs at any time in the early stages, minimizing the cost of errors.

In terms of fixtures, 3D printing technology provides a fast and accurate method that significantly reduces the cost and time of tool production. As a result, automakers have quickly improved in capacity, efficiency and quality.

3D printers recommended

3DSL-600 Hi: Build volume: 600 *600* 400 (mm), Max productivity 400g/h