Medical industry

Medicial Applications

Generally speaking, every patient is a particular medical case, and the customized production mode can meet the demands of these cases. The development of 3D printing technology is pushed by medical applications, and it also brings huge help reciprocally, these include operation AIDS, prosthetics, implants, dentistry, medical teaching, medical instruments, and so on.

Medical assistance:

3D printing makes operations easier, for doctors to make a operation plan, operation preview, guide board and enrich doctor-patient communications.

Medical instruments:

3D printing has made many medical instruments, such as prosthetics, orthotics and artificial ears, easier to make and more affordable for the general public.

Firstly, CT, MRI and other equipment are used to scan and collect the 3D data of the patients. Then, the CT data were reconstructed into 3D data by computer software (Arigin 3D). Finally, the 3D data were made into solid models by 3D printer. And we can use 3d models to assist the operations.

Medical application— Preoperative communication

For high-risk and difficult operations, preoperative planning is very important. Traditionally, patients’ data have been obtained through imaging devices such as CT and MRI, which serve as the basis for doctors’ preoperative planning. However, the obtained medical images are two-dimensional, which is difficult for patients to understand, especially for some complicated lesions, which only read by experienced doctors.

The 3D model of the lesion can be directly printed by the 3D printer, which can not only assist the doctor in accurate surgical planning and improve the success rate of surgery, but also facilitate the communication between the doctor and the patient on the surgical plan. In addition, even after treatment failure, 3D printing can provide a traceable basis for both doctors and patients

Preoperative communication

For complicated operations, doctors can discuss and arrange operations according to the 3d model to obtain the best operation plan.

Surgical guide plate

Surgical guide board is an auxiliary surgical tool to accurately implement the preoperative planning during the operation. It has been applied in many scenarios, such as: arthritis guide plate, spinal guide plate, oral implant guide plate, and positioning guide plate of internal radiation source particle implantation in tumor.

The use of 3D printing preoperative design guidance template or osteotomy template can quickly and accurately locate the lesion location, reduce iatrogenic injury caused by errors, reduce the operation time, shorten the treatment time of patients, which is of great significance for patients’ early activities and early recovery

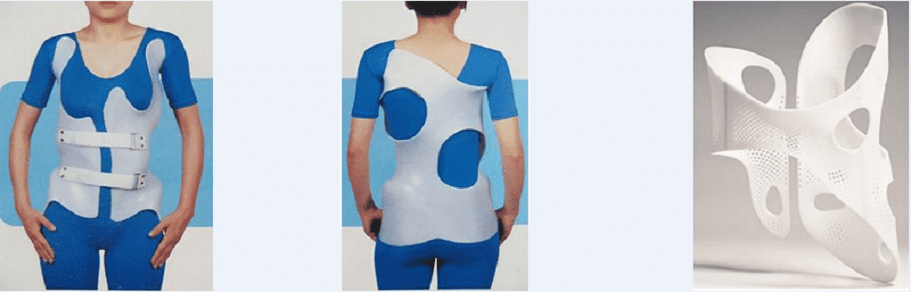

Rehabilitation medical equipment

Prosthetics, hearing aids and other rehabilitation medical devices have small batch, customized demand, and their design are also complicated, traditional CNC machine tools are limited by the processing angle and other factors.3D printing technology is not limited to the structure and appearance, and has the feature of rapid prototyping, which is applicable to the design of personalized products. Therefore, 3D printing technology has been gradually applied to the field of rehabilitation aids. In addition, the cost of producing a single customized rehabilitation aid will be significantly reduced.

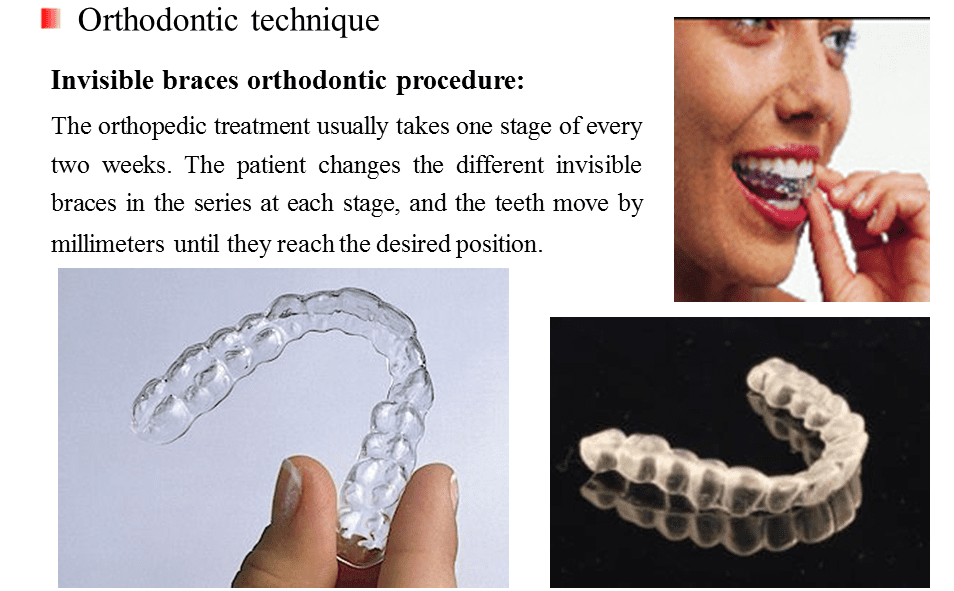

Medical applications – orthodontics

In recent years, software design-based dental restorations have become popular. Many dental clinics, laboratories or professional denture manufacturers have introduced 3D printing technology, which has brought great changes to the dental industry in terms of high precision, low cost and high efficiency. The main applications of 3D printing technology in the dental industry are as follows:

1. Dental molds,

Many dental clinics or laboratories use 3D printers to make models of patients’ teeth. Dental molds can be used as molds to assist in the production of dental crowns, etc., as well as to simulate, plan and communicate the surgical process with patients.

2. Dental implant,

At present, digital implantation is more and more popular in the market. The reason is that the implantation planned by software is more accurate, and the designed implant guide plate and customized implant are more suitable for clinical use.

3. Invisible orthodontics.

Compared with traditional steel wire orthodontics, 3D printed invisible orthodontics is not only invisible and beautiful, but also more suitable for the patient’s tooth state at each stage during the orthodontic period. What’s more, 3D printed orthodontics has an advantage over tradition method, which is mainly rely on experience of dentist.

4. Dental restoration. A metal crown fixed bridge can be made by 3D printing technology, or a resin model of tooth bridge cast by lost-wax process, or even a direct 3D printing of tooth crown can be achieved.

Printer recommended

3DSL-36O Hi (build volume 360*360*300 mm), high efficiency, high accuracy!